PFO, semiconducting polymer for high efficiency green OLEDs

High quality polymer available for fast, secure dispatch

| |

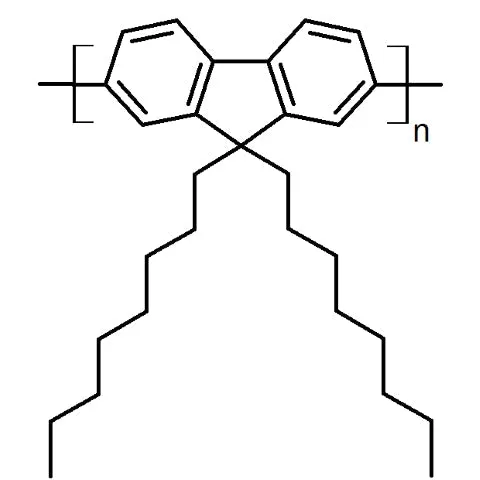

Poly(9,9-di-n-octylfluorenyl-2,7-diyl), known as F8 or PFO, is a polyfluorene specifically optimized for a variety of organic electronic applications.

General Information

| CAS Number | 19456-48-5 |

|---|---|

| Chemical Formula | (C29H41)n |

| Full Name | Poly(9,9-di-n-octylfluorenyl-2,7-diyl) |

| Recommended solvents | Toluene, xylene, chlorobenzene |

| Synonyms | F8 PFO |

| Classification / Family | Polyfluorenes, Benzothiodiazoles, Organic semiconducting materials, Semiconducting polymers, OLED green emitter materials, OLED materials, Organic photovoltaic (OPV) materials, Polymer solar cells, OFET materials |

Chemical Structure

Characterization

Applications

For a high-efficiency green OLED we recommend blending F8 with with the below specifications. This ink can then be applied either in air, or in a glove box, with little difference in performance (provided exposure time and light levels are minimised). .

At typical concentrations of 10 mg/ml, 100 mg of F8 (PFO) will make around 200 devices on Ossila's (20 x 15 mm), assuming 50% solution usage (50% loss in filtering and preparation).

OLED reference device:- F8 with

- Blend ratio of 19:1 (F8:F8BT) in Toluene

- Total concentration of 10 mg/ml

- Spun at 2000 rpm (approx. 70 nm thickness)

Pipetting 20 μl of the above solutions onto a substrate spinning at 2000 rpm should provide a good even coverage, with approximately 70 nm thickness. The substrate needs to be spun until dry, which is typically only a few seconds — 15 seconds should be ample to achieve this. Thermal annealing should be undertaken at 80°C for 10 minutes prior to cathode deposition.

Typical Device Architectures and Performance

A basic, efficient OLED can be made using as a hole-transport layer and Calcium/Aluminum as the electron contact. When used with the Ossila and this produces an easy to fabricate yet efficient >100 cd/m2 device.

MSDS Documentation

Batch Details

| Batch number | MW | MN | PDI | Stock info |

|---|---|---|---|---|

| M161 | 114,050 | 37,910 | 3.00 | Discontinued |

| M162 | 85,983 | 31,040 | 2.77 | Discontinued |

| M163 | 57,798 | 21,328 | 2.71 | Discontinued |

| M164 | 63,114 | 19,125 | 3.30 | Discontinued |

| M0161A1 | 105,491 | 45,275 | 2.33 | Discontinued |

| M0161A2 | 77,293 | 29,167 | 2.65 | Discontinued |

| M0161A3 | 260,817 | 93,709 | 2.78 | In stock |